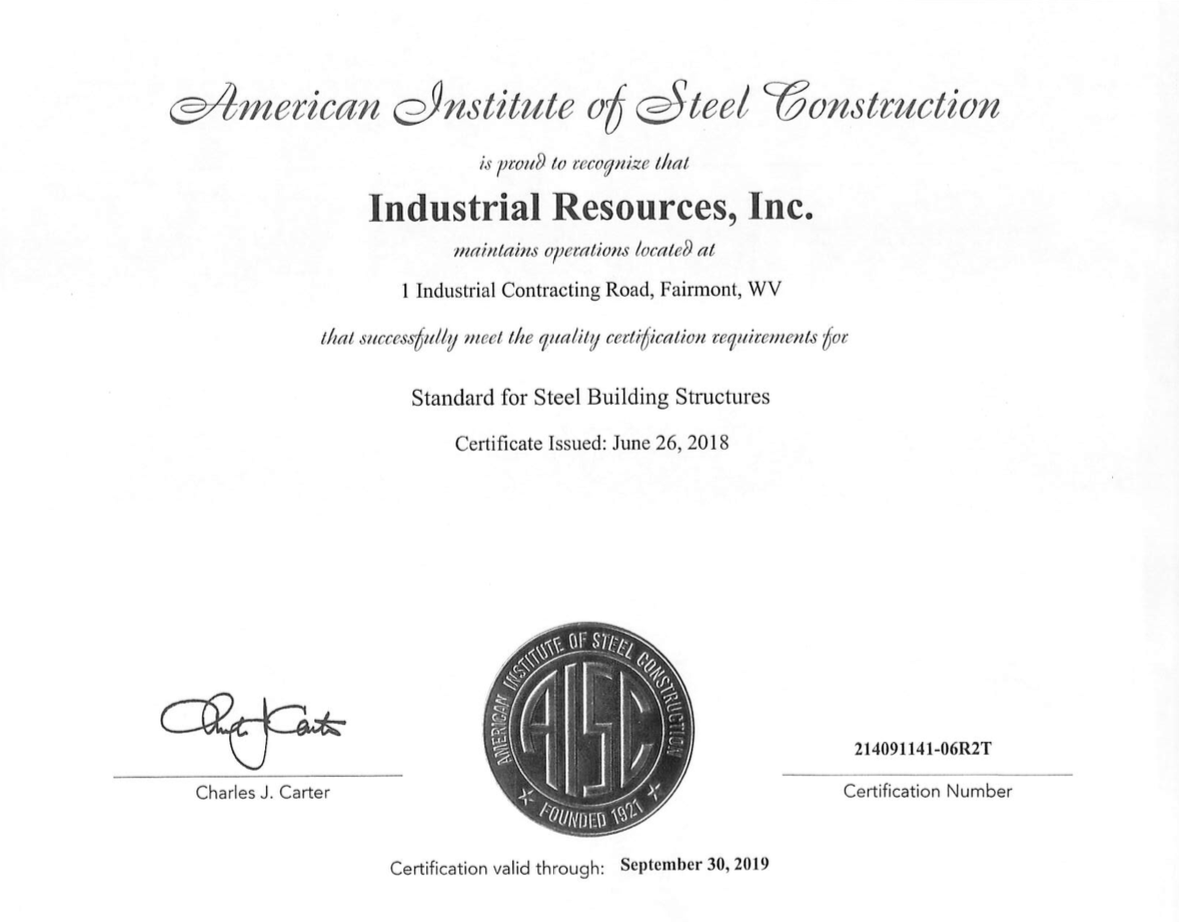

In 2018, we received the American Institute of Steel Construction (AISC) certification for our fourth consecutive year.

Read on to learn more about this certification and what it means for not only us but how it helps the efficiency and quality control of your next project.

2018 American Institute of Steel Construction Certification

Each calendar year it is required that Industrial Resources, Inc., conducts an internal audit of the company’s processes, and then, as required, a third-party company comes to conduct an external audit of those processes that are maintained throughout the year.

The internal and external audits have to be conducted in order to remain an AISC certified fabrication facility.

Craig Doan of Quality Management Company, LLC., conducted the external audit June 12, 2018, and found that Industrial Resources, Inc., maintained all of the requirements of the AISC system without any deficiencies.

“Industrial Resources, Inc., is way ahead of the curve when it comes to performing and maintaining all requirements of the AISC system,” Doan said.

“There are not many AISC certified companies in West Virginia,” said Phil Burnside, president of Industrial Resources, Inc. “We are very proud of this certification achievement.”

Industrial Resources, Inc., has been AISC certified since 2014. The process to become certified is very involved and takes a lot of time and effort. The 2018 certification was approved and extended through September 30, 2019, and represents that Industrial Resources Inc., conforms to the standards of steel building structures.

What are the Requirements to Become AISC Certified?

To become AISC certified, there can be many requirements, including:

- Certification of all welders

- Continuously measuring

- Calibrating the equipment

- Following all welding procedures

- Inspection of all welds

- Testing bolts to make sure they meet the RCSC specifications

- Measuring surface preparation

- Testing Dry Film Thickness of paint application

- Final inspection of components prior to delivery

Does an AISC Fabricator Add Value to a Project?

A certified fabricator provides a higher level of quality control and quality assurance for your project, which is in accordance with the recognized industry standards, codes and practices.

“Industrial Resources, Inc., is 100 percent committed to fulfilling the obligations of the AISC quality management system and providing its customers with project quality second to none,” Burnside said.

Should You Consider Constructing a Steel Structure?

A structural steel project can accomplish any design that an architect imagines. Structural steel can adapt quickly and efficiently without needing to change floor plans significantly.

Not only can it adapt easily, structural steel is cost-efficient:

- Lower foundation costs: it has an increased strength-to-weight ratio

- Construction costs: structural steel can be erected faster, which decreases hours spent on labor

- Increased revenue: since the structure can be erected at a much quicker rate, the building can be used earlier than expected

- Future costs: since structural steel is easily adaptable, any future changes will not be as expensive.

According to the American Institute of Steel Construction:

“Using BIM (building information modeling) can further reduce the overall cost of a steel building. In fact, studies have shown that this integrated approach can reduce the cost of a steel package by 10 percent to 20 percent.”

Learn more about why you should use structural steel in your project here.

Industrial Resources, Inc. | American Institute of Steel Construction Certified

Industrial Resources, Inc., is a turnkey contractor that designs, details, engineers, fabricates and constructs custom facilities.

The corporate office is located in Fairmont, West Virginia, with a professional engineering division office is located in Carnegie, Pennsylvania.

Industrial Resources, Inc., also has a professional electrical engineering group and facility in Pleasant Valley, Fairmont., West Virginia.